Rongda Product recommend

Rongda Composite Material is a new modern private enterprise integrating R & D, production, export and integration.

In recent years, in order to meet the needs of more and more customers, we have extended the embossing service vertically. On the basis of using our own galvanized, aluminized zinc and color coated substrates, we can provide our customers with excellent quality embossing plates. Embossed plate (I. e. corrugated board) is based on the shear steel plate for deeper processing, widely used in civil buildings, warehouses, special buildings, large-span steel structure housing roof, wall and interior and exterior wall decoration. The pressure tile board produced by our company must go through strict quality inspection procedures to ensure that every process is kept improving. In particular, the number of meters and pieces that customers are most concerned about, we have to go through strict before the products leave the factory.

In recent years, in order to meet the needs of more and more customers, we have extended the embossing service vertically. On the basis of using our own galvanized, aluminized zinc and color coated substrates, we can provide our customers with excellent quality embossing plates. The embossing plate is a concave-convex pattern on the surface of the steel plate, which is used in places where the finish and ornamental are required. The embossing plates produced by our company have to go through strict quality inspection procedures to ensure that each process is kept improving. In particular, the number of meters and pieces that customers are most concerned about, we have to go through strict inspection before the products leave the factory to ensure the accuracy of the quantity. In addition, in order to make the product surface smooth and beautiful, we have a

In recent years, in order to meet the needs of more and more customers, we have extended the embossing service vertically. On the basis of using our own galvanized, aluminized zinc and color coated substrates, we can provide our customers with excellent quality embossing plates. The embossing plate is a concave-convex pattern on the surface of the steel plate, which is used in places where the finish and ornamental are required. The embossing plates produced by our company have to go through strict quality inspection procedures to ensure that each process is kept improving. In particular, the number of meters and pieces that customers are most concerned about, we have to go through strict inspection before the products leave the factory to ensure the accuracy of the quantity. In addition, in order to make the product surface smooth and beautiful, we have a

In recent years, in order to meet the needs of more and more customers, we have extended the Kaiping service vertically. On the basis of using our own galvanized, aluminized zinc and color coated substrates, we can provide our customers with excellent quality open plates. Open plate is commonly known as shear steel plate, shear steel plate belongs to the metallurgical mineral industry, subdivided into a category of coating products, has been recognized by the majority of customers. In the revised GB709, the open plate and the original plate should be called: single rolled steel plate and shear steel plate. When the steel plate comes out of the steel mill, it is rolled. The flat plate after these steel plates are leveled by the leveler is called "open plate", which is good.

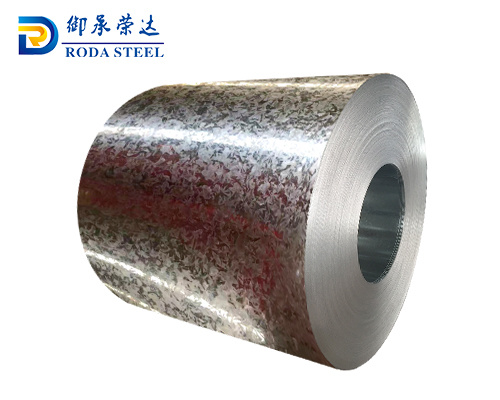

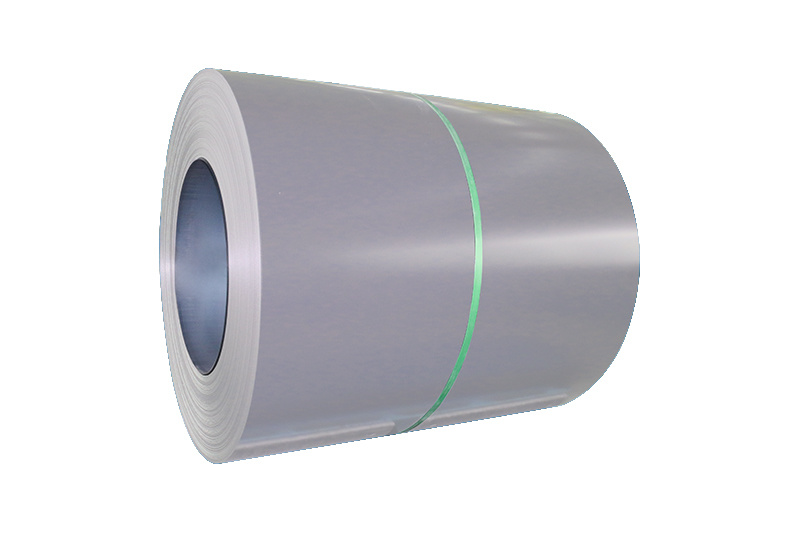

Galvanized plate-process flow production process a, cold and hot rolled steel plate is degreased by alkali washing, washed with water, dried and then annealed in a horizontal (vertical) heating furnace heated by radiant tubes, and a certain amount of hydrogen is introduced into the furnace to create a reducing atmosphere in the furnace; B, steel strip heated to a certain temperature is immersed in zinc solution for hot dip galvanizing under certain conditions. After the strip steel immersed in zinc liquid comes out of the zinc pot, the amount of zinc plating is controlled by an air knife. C, the size of zinc flower is controlled by the composition of liquid zinc, and at the same time, the forced cooling method is adopted. Before the zinc flower starts to diffuse, the small zinc flower product is quenched with the small zinc flower equipment to prevent the zinc liquid from continuing to diffuse and form small zinc flower.

Galvanized plate-process flow production process a, cold and hot rolled steel plate is degreased by alkali washing, washed with water, dried and then annealed in a horizontal (vertical) heating furnace heated by radiant tubes, and a certain amount of hydrogen is introduced into the furnace to create a reducing atmosphere in the furnace; B, steel strip heated to a certain temperature is immersed in zinc solution for hot dip galvanizing under certain conditions. After the strip steel immersed in zinc liquid comes out of the zinc pot, the amount of zinc plating is controlled by an air knife. C, the size of zinc flower is controlled by the composition of liquid zinc, and at the same time, the forced cooling method is adopted. Before the zinc flower starts to diffuse, the small zinc flower product is quenched with the small zinc flower equipment to prevent the zinc liquid from continuing to diffuse and form small zinc flower.

Galvanized plate-process flow production process a, cold and hot rolled steel plate is degreased by alkali washing, washed with water, dried and then annealed in a horizontal (vertical) heating furnace heated by radiant tubes, and a certain amount of hydrogen is introduced into the furnace to create a reducing atmosphere in the furnace; B, steel strip heated to a certain temperature is immersed in zinc solution for hot dip galvanizing under certain conditions. After the strip steel immersed in zinc liquid comes out of the zinc pot, the amount of zinc plating is controlled by an air knife. C, the size of zinc flower is controlled by the composition of liquid zinc, and at the same time, the forced cooling method is adopted. Before the zinc flower starts to diffuse, the small zinc flower product is quenched with the small zinc flower equipment to prevent the zinc liquid from continuing to diffuse and form small zinc flower.

Galvanized plate-process flow production process a, cold and hot rolled steel plate is degreased by alkali washing, washed with water, dried and then annealed in a horizontal (vertical) heating furnace heated by radiant tubes, and a certain amount of hydrogen is introduced into the furnace to create a reducing atmosphere in the furnace; B, steel strip heated to a certain temperature is immersed in zinc solution for hot dip galvanizing under certain conditions. After the strip steel immersed in zinc liquid comes out of the zinc pot, the amount of zinc plating is controlled by an air knife. C, the size of zinc flower is controlled by the composition of liquid zinc, and at the same time, the forced cooling method is adopted. Before the zinc flower starts to diffuse, the small zinc flower product is quenched with the small zinc flower equipment to prevent the zinc liquid from continuing to diffuse and form small zinc flower.

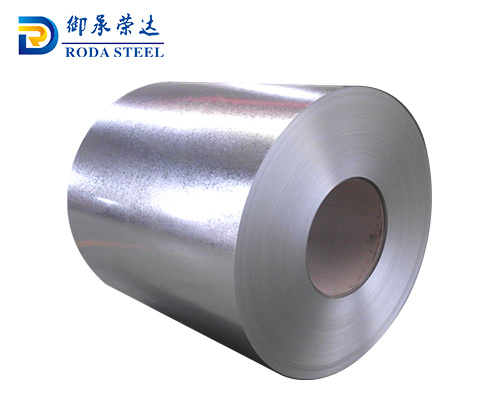

The hot-dip aluminum-zinc steel plate is a cold-rolled steel plate with various strength and thickness specifications as the base material, and a AL-ZN aluminum-zinc alloy coating is hot-dipped on both sides. The obtained pre-coated steel plate has a mass percentage of about 55% Al aluminum, 43.5 ZN zinc and 1.6 Si silicon in the coating composition. It combines the physical protection and high durability of AL and the electrochemical protection of ZN. In addition, on the surface is a highly decorative bright silver gray and specifications of the fish scale pattern, and has a three-dimensional relief feeling. The two important elements of the plating plate are zinc, aluminum, aluminum and zinc, three kinds of alloy materials. Zinc is generally represented by Z. Z is English Zi

The hot-dip aluminum-zinc steel plate is a cold-rolled steel plate with various strength and thickness specifications as the base material, and a AL-ZN aluminum-zinc alloy coating is hot-dipped on both sides. The obtained pre-coated steel plate has a mass percentage of about 55% Al aluminum, 43.5 ZN zinc and 1.6 Si silicon in the coating composition. It combines the physical protection and high durability of AL and the electrochemical protection of ZN. In addition, on the surface is a highly decorative bright silver gray and specifications of the fish scale pattern, and has a three-dimensional relief feeling. The two important elements of the plating plate are zinc, aluminum, aluminum and zinc, three kinds of alloy materials. Zinc is generally represented by Z. Z is English Zi

The hot-dip aluminum-zinc steel plate is a cold-rolled steel plate with various strength and thickness specifications as the base material, and a AL-ZN aluminum-zinc alloy coating is hot-dipped on both sides. The obtained pre-coated steel plate has a mass percentage of about 55% Al aluminum, 43.5 ZN zinc and 1.6 Si silicon in the coating composition. It combines the physical protection and high durability of AL and the electrochemical protection of ZN. In addition, on the surface is a highly decorative bright silver gray and specifications of the fish scale pattern, and has a three-dimensional relief feeling. The two important elements of the plating plate are zinc, aluminum, aluminum and zinc, three kinds of alloy materials. Zinc is generally represented by Z. Z is English Zi

The hot-dip aluminum-zinc steel plate is a cold-rolled steel plate with various strength and thickness specifications as the base material, and a AL-ZN aluminum-zinc alloy coating is hot-dipped on both sides. The obtained pre-coated steel plate has a mass percentage of about 55% Al aluminum, 43.5 ZN zinc and 1.6 Si silicon in the coating composition. It combines the physical protection and high durability of AL and the electrochemical protection of ZN. In addition, on the surface is a highly decorative bright silver gray and specifications of the fish scale pattern, and has a three-dimensional relief feeling. The two important elements of the plating plate are zinc, aluminum, aluminum and zinc, three kinds of alloy materials. Zinc is generally represented by Z. Z is English Zi

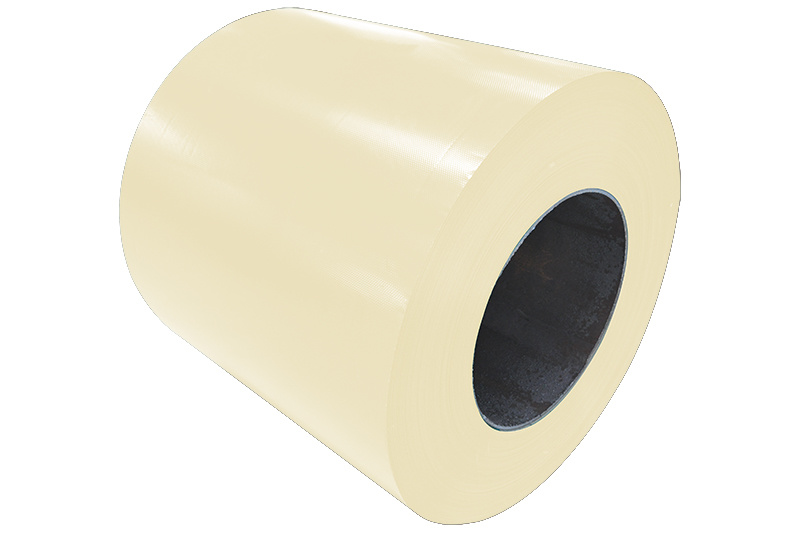

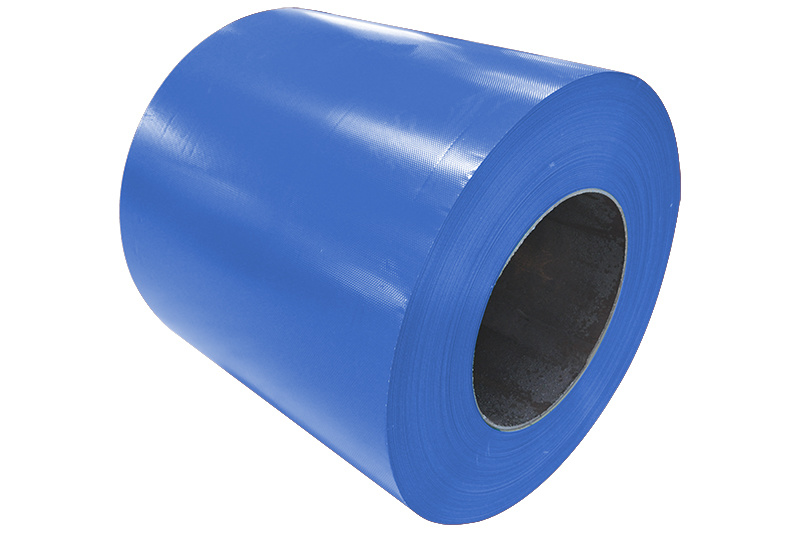

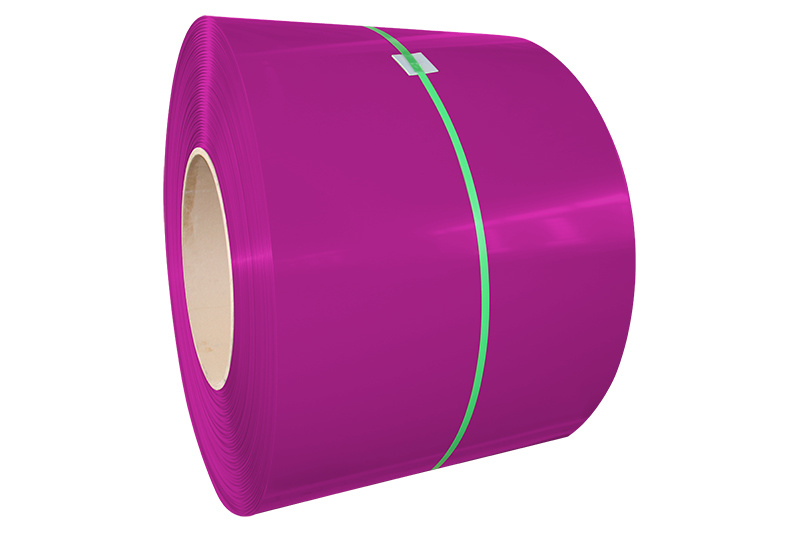

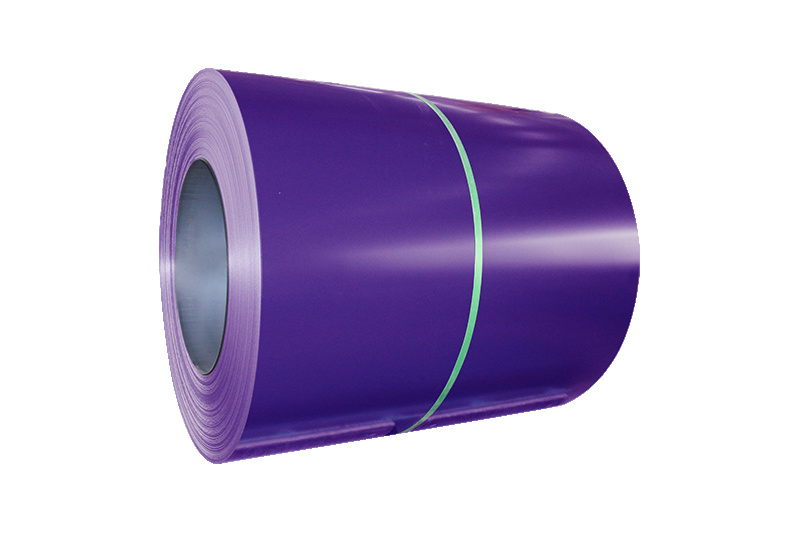

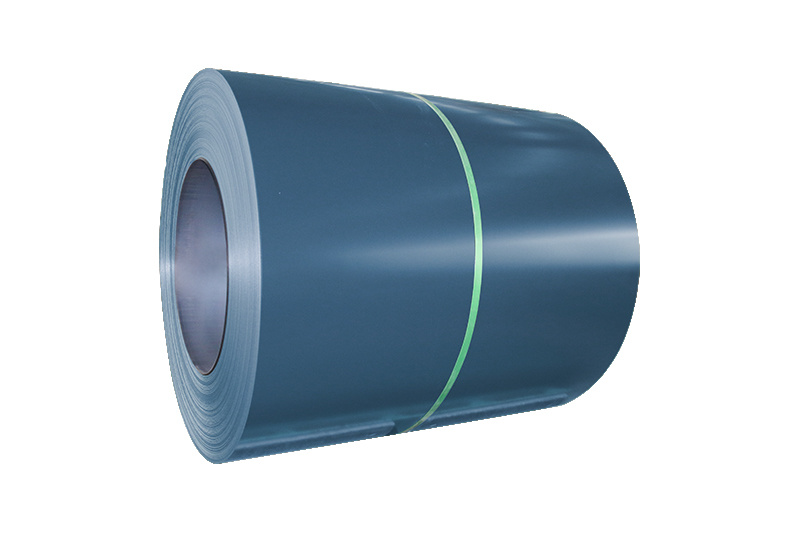

Color coated steel plate is a new type of steel strip pre-coating product developed rapidly in the world in the past 30 years. It is refined by chemical pretreatment, primary coating, finish coating and other processes on high-speed continuous unit. The coating quality is far more uniform, stable and ideal than the quality of single-piece spraying or brushing on the formed metal surface;

Color coated steel plate is a new type of steel strip pre-coating product developed rapidly in the world in the past 30 years. It is refined by chemical pretreatment, primary coating, finish coating and other processes on high-speed continuous unit. The coating quality is far more uniform, stable and ideal than the quality of single-piece spraying or brushing on the formed metal surface;

Color coated steel plate is a new type of steel strip pre-coating product developed rapidly in the world in the past 30 years. It is refined by chemical pretreatment, primary coating, finish coating and other processes on high-speed continuous unit. The coating quality is far more uniform, stable and ideal than the quality of single-piece spraying or brushing on the formed metal surface;

Color coated steel plate is a new type of steel strip pre-coating product developed rapidly in the world in the past 30 years. It is refined by chemical pretreatment, primary coating, finish coating and other processes on high-speed continuous unit. The coating quality is far more uniform, stable and ideal than the quality of single-piece spraying or brushing on the formed metal surface;

Color coated steel plate is a new type of steel strip pre-coating product developed rapidly in the world in the past 30 years. It is refined by chemical pretreatment, primary coating, finish coating and other processes on high-speed continuous unit. The coating quality is far more uniform, stable and ideal than the quality of single-piece spraying or brushing on the formed metal surface;

In recent years, in order to meet the needs of more and more customers, we have extended the embossing service vertically. On the basis of using our own galvanized, aluminized zinc and color coated substrates, we can provide our customers with excellent quality embossing plates. Embossed plate (I. e. corrugated board) is based on the shear steel plate for deeper processing, widely used in civil buildings, warehouses, special buildings, large-span steel structure housing roof, wall and interior and exterior wall decoration. The pressure tile board produced by our company must go through strict quality inspection procedures to ensure that every process is kept improving. In particular, the number of meters and pieces that customers are most concerned about, we have to go through strict before the products leave the factory.

Product application field

Products are mainly used in the automotive industry, plant construction, construction and other fields

RONGDA

Rongda Composites

Precision machinery

Why choose Rongda composite materials?

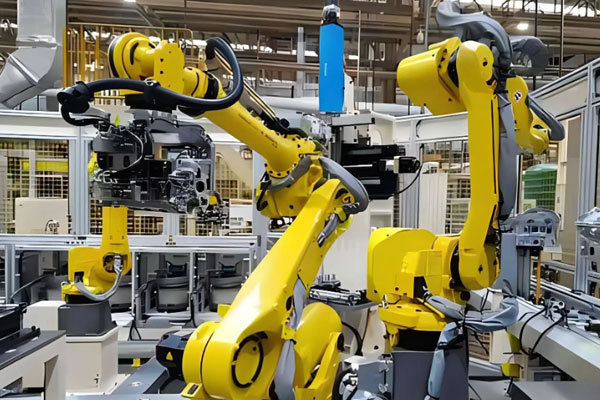

The company has advanced professional production equipment and mature technology

Advanced production process

The company has advanced professional production equipment and mature technology, but also has a high-quality professional management and technical personnel.

production scale

It has formed an annual capacity of 350000 tons of aluminum and zinc plating, 100000 tons of galvanized sheet and 200000 tons of color coated sheet.

On-Demand Customized Delivery

Three characteristics of the company: special color, special specifications (thickness: 0.10MM-4.0MM, width: 720MM-1250MM), special material (G550 high strength).

9 years manufacturing experience

60 million of registered capital

Products sold to more than 50 countries

Cumulative Customer Service

Shandong Guanxian Rongda Composite Material Co., Ltd.

Shandong Guanxian Rongda Composite Material Co., Ltd. was established in 2016. It is a new modern private enterprise integrating R & D, production, export and integration. The company is located in Liaocheng City, Shandong Province, a national excellent city known as "Jiangbei Water City", with a registered capital of 60 million yuan, covering an area of more than 100 mu, a construction area of 50000 square meters and more than 300 employees. The company has advanced professional production equipment and mature technology, and has a team of high-quality professional management and technical personnel. The company has passed the international quality management body ISO9001:2000 certification. It has formed an annual capacity of 350000 tons of aluminum and zinc plating, 100000 tons of galvanized sheet and 200000 tons of color coated sheet. Scope of business: color coated plate, galvanized plate, aluminized zinc plate (fingerprint resistant), cold rolled, wave tile, T-tile and embossed products. The company has three characteristics: special color, special specification (thickness: 0.10MM-4.0MM, width: 700MM-1250MM) and special material (G550 high strength). Products are mainly used in the automotive industry, plant construction, construction and other fields. The company's products have been exported to Africa, the Middle East, South America, Southeast Asia, Central Asia and other countries.

Learn more>>

Focus on the latest development of Rongda

The company has passed the international quality management body ISO9001:2000 certification, the company has exported to Indonesia SNI and Malaysia SIRIM certification.

2021-06-13

Cleaner production information publicity

2021-05-02

2020-11-27

Shandong Guanxian Rongda Composite Material Co., Ltd.

2020-06-22

Bless China! Bless the world! -Xi Jinping's 2019 New Year Message Revelation

2019-01-22

How the embossing roller is made

2016-08-22