Color coated roll

Key words:

Color coated roll

Classification:

Product Description

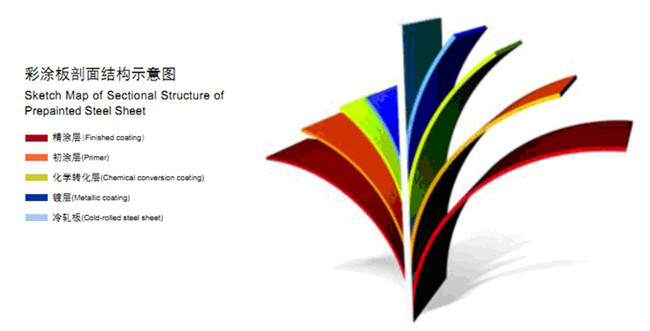

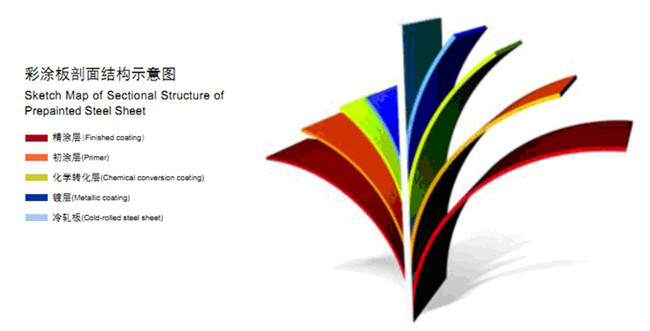

Color coated steel plate is a new type of steel strip pre-coating product developed rapidly in the world in the past 30 years. It is refined by chemical pretreatment, primary coating, finish coating and other processes on high-speed continuous unit. The coating quality is far more uniform, stable and ideal than the quality of single-piece spraying or brushing on the formed metal surface;

The color coated steel plate has excellent decoration, formability, corrosion resistance, strong coating adhesion, and can maintain a novel color for a long time. Because the color coated steel plate can take the steel instead of wood, efficient construction, energy saving, pollution prevention and other good economic benefits, it has become the ideal material for the manufacture of building plates.

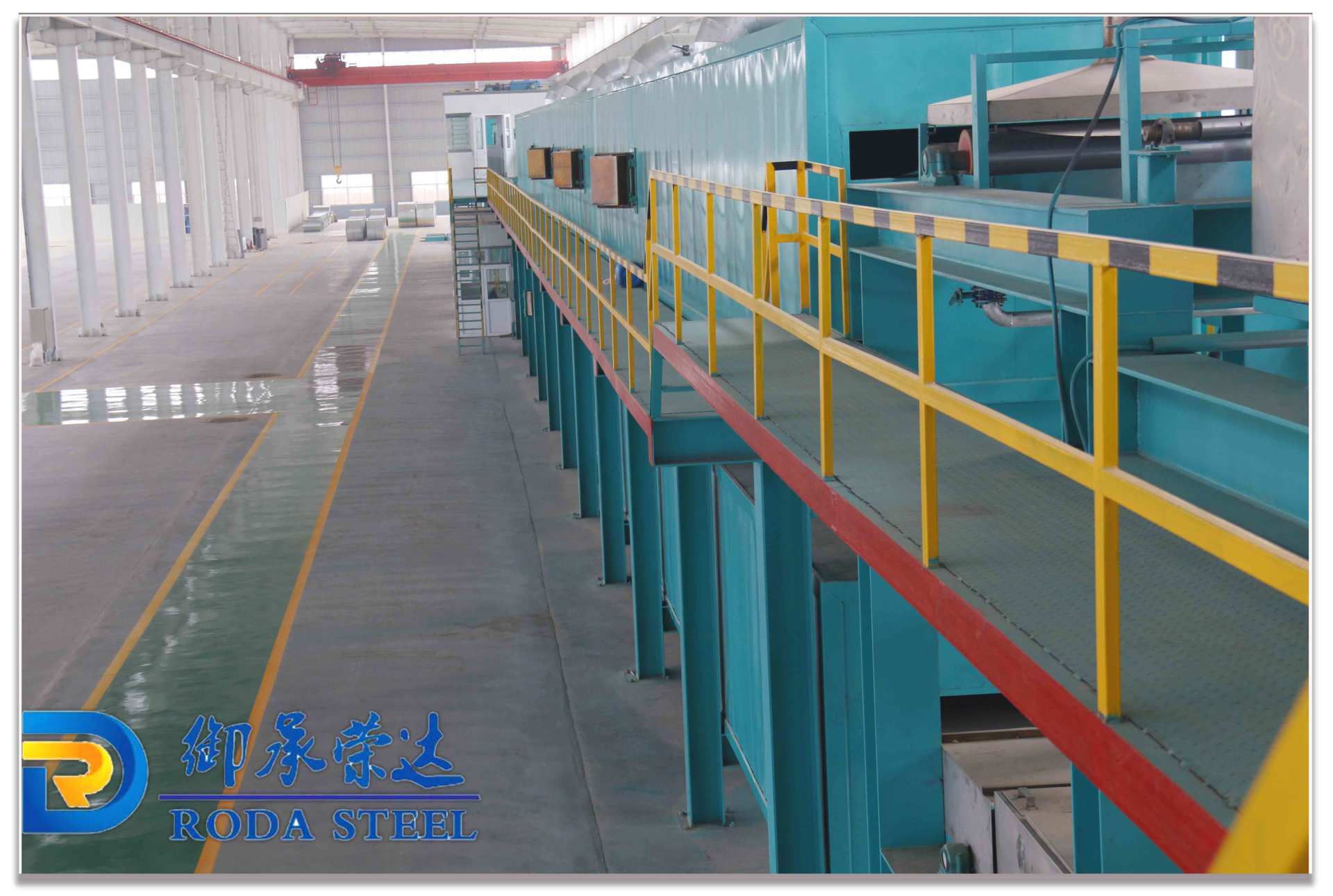

Rongda Company, as a manufacturer starting with color-coated steel plates, has been committed to being a professional color-coated steel plate manufacturer with high quality plates. At present, the company has advanced color-coated automatic units and continuously improves its product technology, with an annual output of 200000 tons. Over the years, the color coated board of Rongda brand has spread all over the world.

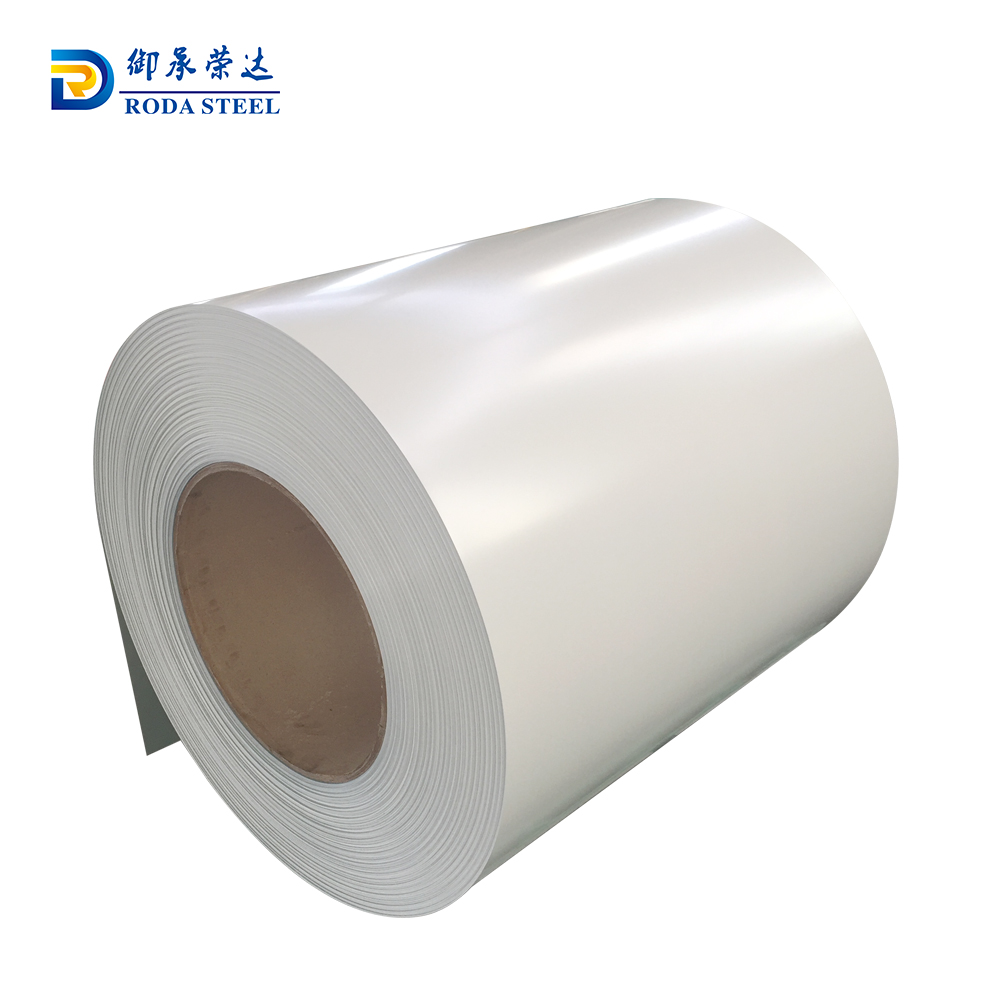

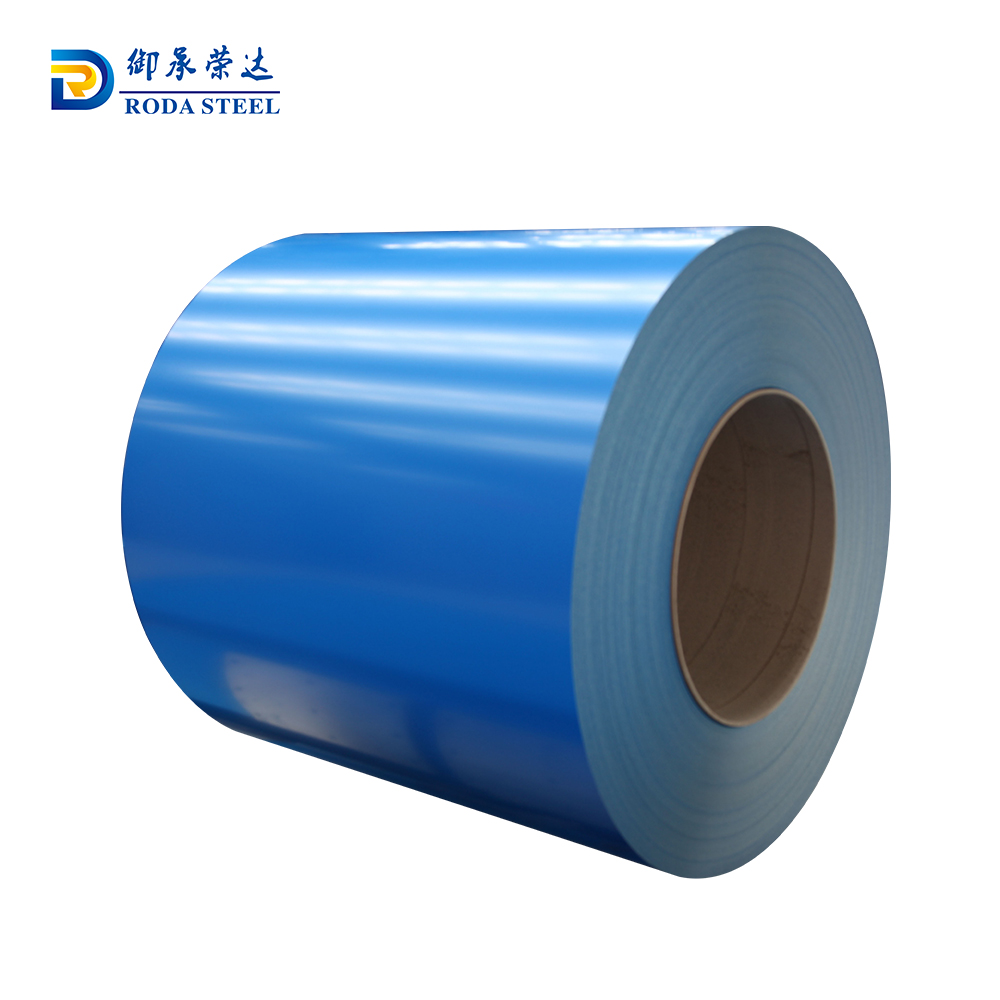

Rongda's color coating products are mainly divided into two categories: ordinary color coating and reticulated color coating. Various colors can be selected according to the Raul color card. Color can also be deployed according to customer samples. Reticulated products can also be subdivided into large reticulated and small reticulated. Specific requirements can be based on customer conditions and our business depth of communication, so that other customers to achieve the most satisfactory results.

Specification Performance

1. Thickness (mm):0.13-1.0;

2. Length (mm): Due to continuous molding production, the board length can be determined according to user needs;

3. Width (mm):750~1250

|  |

Color steel plate detailed explanation

1. basic characteristics

1. Light weight: 10-14kg/m2, equivalent to 1/30 of brick wall.

2. Thermal insulation: thermal conductivity of core material: λ<= 0.041w/mk.

3. High strength: it can be used as ceiling enclosure structure plate bearing, bending and compression resistance; general houses do not use beams and columns.

4. bright color: no surface decoration, color galvanized steel plate anticorrosive layer to maintain the period of 10-15 years.

Flexible and fast installation: the construction period can be shortened by more than 40%.

6. Oxygen index:(OI)32.0 (provincial fire product quality inspection station).

Main types of 2.

The substrate of the color steel plate is cold-rolled substrate, hot-dip galvanized substrate and electro-galvanized substrate. Coating types can be divided into polyester, silicon modified polyester, vinylidene fluoride and plastisol. The surface state of color steel plate can be divided into coated plate, embossed plate and printed plate, color steel plate is widely used in construction appliances and transportation and other industries, for the construction industry is mainly used for steel structure factory building, airport, warehouse and refrigeration and other industrial and commercial buildings, such as the roof wall and door, civil construction using color steel plate less.

Difference with plastic steel

The difference between it and plastic steel is that the composition of the material is different, and the magnet can be sucked.

Strictly speaking, plastic steel and color steel in the metal characteristics and surface treatment can not be very good distinction, because the same; so the distinction between the market mainly in the profile structure.

magnet test

Because it is ordinary carbon steel material, magnet can suck. In addition, stainless steel is the product of adding chromium (greater than or equal to 13%) on the basis of low carbon steel, so the magnet cannot be sucked.

3. development trend

First, the high-quality substrate is adopted, and the requirements for the surface, shape and dimensional accuracy of the substrate are getting higher and higher. For outdoor use, such as small zinc-flowered flat hot-dip galvanized steel coils and zinc-free flat hot-dip galvanized steel coils, zinc-alloy hot-dip galvanized steel coils that rise in time; Indoor use such as electrogalvanized steel coils, film cold-rolled plates and aluminum coils.

Second, improve the pretreatment process and pretreatment liquid, the number of equipment is small, low cost has become the mainstream process, and continuously improve the stability, corrosion resistance and environmental protection performance of the pretreatment liquid.

Third, pay attention to the development of new coatings, improve the general polyester, polyvinylidene fluoride (PVDF) and plastisol to obtain super color reproducibility, anti-ultraviolet, anti-sulfur dioxide, and improve corrosion resistance; develop pollution-resistant, heat-absorbing and other functional coatings.

Fourth, the unit equipment is more perfect. Such as the use of new welding machine, new roller coating machine, improve the curing furnace, the configuration of advanced automation instruments.

Fifth, due to the low cost of cold embossing than hot embossing, it has the characteristics of beauty, three-dimensional effect, and high strength, so that cold embossing production technology has become a development trend.

Sixth, pay attention to the diversification, functionalization, and high-grade products, such as deep-drawn color-coated boards, "grapefruit peel" color-coated boards, anti-static color-coated boards, pollution-resistant color-coated boards, and high-heat-absorbing color-coated boards.

4. characteristic performance

Color steel plate coating is cold rolled steel plate, galvanized steel plate, surface chemical treatment after coating (roller coating) or composite organic film (PVC film, etc.), and then baked and cured products. Some people also call this product "pre-roll color steel plate" and "plastic color steel plate". Color plate products are produced by manufacturers in continuous production lines, so they are also called color coated steel plates. Color steel plate not only has the high mechanical strength of steel material, easy to form the performance, but also has the good decoration and corrosion resistance of the coating material. Color steel plate is a new material respected in the world today. With the advancement of science and technology, the enhancement of environmental awareness, and the improvement of people's living standards, color steel plate activity houses are increasingly showing strong vitality and broad market prospects. They are favored by construction, home appliances, electromechanical, transportation, interior decoration, office appliances and other industries.

Color steel plate activity room has the advantages of light weight, high strength, thermal insulation, beautiful and durable. It is a high-level building installation which integrates architecture and decoration. The construction of color steel plate movable house is clean, and is widely used in large-span factories, warehouses, office buildings, villas, roof layers, air purification rooms, cold storage, shops, kiosks and temporary rooms. Light color steel plate sandwich panel square meter weight less than 14KG can fully reduce the structural load, reduce the cost of mobile house structure.

Easy installation

Color steel plate activity room light weight, splicing installation and can be free to cut the characteristics, determine the activity room installation is simple, can greatly improve the efficiency, save time. The surface material and thermal insulation material of fireproof color steel plate sandwich panel are non combustible materials, which can fully meet the requirements of fire protection standard of movable room.

Durability

A variety of studies have shown that it has been widely used abroad for more than 40 years to confirm that the shelf life of the color steel plate treated by special coating is 10-15 years, and the anti-corrosion coating is sprayed every 10 years, and the service life of the movable room plate can reach more than 35 years.

Beautiful

The color steel plate has clear lines of up to dozens of colors, which can be used to meet the needs of any style of mobile buildings to achieve satisfactory results.

5. composition application

1. The substrate of color steel plate can be divided into cold rolled substrate, hot dip galvanized substrate and electro galvanized substrate.

2. The coating types of color steel plate can be divided into: polyester, silicon modified polyester, vinylidene fluoride, plastisol.

3. The color of the color steel plate can be divided into many types according to the requirements of users, such as orange, milk yellow, deep sky blue, navy, crimson, brick red, ivory, porcelain blue, etc.

4, the surface state of the color steel plate can be divided into coated plate, embossing plate, printing plate.

5. The market use of color coated steel plate is mainly divided into three parts: construction, home appliances and transportation. Among them, the construction field accounts for the largest proportion, followed by the home appliance industry, and the transportation industry only accounts for a small part.

Color steel plates for construction are generally made of hot-dip galvanized steel plates and hot-dip aluminum-zinc steel plates as substrates, which are mainly processed into corrugated plates or composite sandwich panels with polyurethane for the construction of steel structure factories, airports, warehouses, freezers and other industrial and commercial buildings. Roof, wall, door.

Home appliance color plates are generally electrogalvanized and cold plates as substrates for the production of refrigerators and large air conditioning systems, freezers, bread machines, furniture, etc.

In the transportation industry, electro-galvanized and cold plates are generally used as substrates, mainly for oil pans, automotive interior parts, etc.

- Product Description

-

- Commodity name: Color coated roll

Color coated steel plate is a new type of steel strip pre-coating product developed rapidly in the world in the past 30 years. It is refined by chemical pretreatment, primary coating, finish coating and other processes on high-speed continuous unit. The coating quality is far more uniform, stable and ideal than the quality of single-piece spraying or brushing on the formed metal surface;

Color coated steel plate is a new type of steel strip pre-coating product developed rapidly in the world in the past 30 years. It is refined by chemical pretreatment, primary coating, finish coating and other processes on high-speed continuous unit. The coating quality is far more uniform, stable and ideal than the quality of single-piece spraying or brushing on the formed metal surface;

The color coated steel plate has excellent decoration, formability, corrosion resistance, strong coating adhesion, and can maintain a novel color for a long time. Because the color coated steel plate can take the steel instead of wood, efficient construction, energy saving, pollution prevention and other good economic benefits, it has become the ideal material for the manufacture of building plates.

Rongda Company, as a manufacturer starting with color-coated steel plates, has been committed to being a professional color-coated steel plate manufacturer with high quality plates. At present, the company has advanced color-coated automatic units and continuously improves its product technology, with an annual output of 200000 tons. Over the years, the color coated board of Rongda brand has spread all over the world.

Rongda's color coating products are mainly divided into two categories: ordinary color coating and reticulated color coating. Various colors can be selected according to the Raul color card. Color can also be deployed according to customer samples. Reticulated products can also be subdivided into large reticulated and small reticulated. Specific requirements can be based on customer conditions and our business depth of communication, so that other customers to achieve the most satisfactory results.

Specification Performance

1. Thickness (mm):0.13-1.0;

2. Length (mm): Due to continuous molding production, the board length can be determined according to user needs;

3. Width (mm):750~1250

Color steel plate detailed explanation

1. basic characteristics

1. Light weight: 10-14kg/m2, equivalent to 1/30 of brick wall.

2. Thermal insulation: thermal conductivity of core material: λ<= 0.041w/mk.

3. High strength: it can be used as ceiling enclosure structure plate bearing, bending and compression resistance; general houses do not use beams and columns.

4. bright color: no surface decoration, color galvanized steel plate anticorrosive layer to maintain the period of 10-15 years.

Flexible and fast installation: the construction period can be shortened by more than 40%.

6. Oxygen index:(OI)32.0 (provincial fire product quality inspection station).

Main types of 2.

The substrate of the color steel plate is cold-rolled substrate, hot-dip galvanized substrate and electro-galvanized substrate. Coating types can be divided into polyester, silicon modified polyester, vinylidene fluoride and plastisol. The surface state of color steel plate can be divided into coated plate, embossed plate and printed plate, color steel plate is widely used in construction appliances and transportation and other industries, for the construction industry is mainly used for steel structure factory building, airport, warehouse and refrigeration and other industrial and commercial buildings, such as the roof wall and door, civil construction using color steel plate less.

Difference with plastic steel

The difference between it and plastic steel is that the composition of the material is different, and the magnet can be sucked.

Strictly speaking, plastic steel and color steel in the metal characteristics and surface treatment can not be very good distinction, because the same; so the distinction between the market mainly in the profile structure.

magnet test

Because it is ordinary carbon steel material, magnet can suck. In addition, stainless steel is the product of adding chromium (greater than or equal to 13%) on the basis of low carbon steel, so the magnet cannot be sucked.

3. development trend

First, the high-quality substrate is adopted, and the requirements for the surface, shape and dimensional accuracy of the substrate are getting higher and higher. For outdoor use, such as small zinc-flowered flat hot-dip galvanized steel coils and zinc-free flat hot-dip galvanized steel coils, zinc-alloy hot-dip galvanized steel coils that rise in time; Indoor use such as electrogalvanized steel coils, film cold-rolled plates and aluminum coils.

Second, improve the pretreatment process and pretreatment liquid, the number of equipment is small, low cost has become the mainstream process, and continuously improve the stability, corrosion resistance and environmental protection performance of the pretreatment liquid.

Third, pay attention to the development of new coatings, improve the general polyester, polyvinylidene fluoride (PVDF) and plastisol to obtain super color reproducibility, anti-ultraviolet, anti-sulfur dioxide, and improve corrosion resistance; develop pollution-resistant, heat-absorbing and other functional coatings.

Fourth, the unit equipment is more perfect. Such as the use of new welding machine, new roller coating machine, improve the curing furnace, the configuration of advanced automation instruments.

Fifth, due to the low cost of cold embossing than hot embossing, it has the characteristics of beauty, three-dimensional effect, and high strength, so that cold embossing production technology has become a development trend.

Sixth, pay attention to the diversification, functionalization, and high-grade products, such as deep-drawn color-coated boards, "grapefruit peel" color-coated boards, anti-static color-coated boards, pollution-resistant color-coated boards, and high-heat-absorbing color-coated boards.

4. characteristic performance

Color steel plate coating is cold rolled steel plate, galvanized steel plate, surface chemical treatment after coating (roller coating) or composite organic film (PVC film, etc.), and then baked and cured products. Some people also call this product "pre-roll color steel plate" and "plastic color steel plate". Color plate products are produced by manufacturers in continuous production lines, so they are also called color coated steel plates. Color steel plate not only has the high mechanical strength of steel material, easy to form the performance, but also has the good decoration and corrosion resistance of the coating material. Color steel plate is a new material respected in the world today. With the advancement of science and technology, the enhancement of environmental awareness, and the improvement of people's living standards, color steel plate activity houses are increasingly showing strong vitality and broad market prospects. They are favored by construction, home appliances, electromechanical, transportation, interior decoration, office appliances and other industries.

Color steel plate activity room has the advantages of light weight, high strength, thermal insulation, beautiful and durable. It is a high-level building installation which integrates architecture and decoration. The construction of color steel plate movable house is clean, and is widely used in large-span factories, warehouses, office buildings, villas, roof layers, air purification rooms, cold storage, shops, kiosks and temporary rooms. Light color steel plate sandwich panel square meter weight less than 14KG can fully reduce the structural load, reduce the cost of mobile house structure.

Easy installation

Color steel plate activity room light weight, splicing installation and can be free to cut the characteristics, determine the activity room installation is simple, can greatly improve the efficiency, save time. The surface material and thermal insulation material of fireproof color steel plate sandwich panel are non combustible materials, which can fully meet the requirements of fire protection standard of movable room.

Durability

A variety of studies have shown that it has been widely used abroad for more than 40 years to confirm that the shelf life of the color steel plate treated by special coating is 10-15 years, and the anti-corrosion coating is sprayed every 10 years, and the service life of the movable room plate can reach more than 35 years.

Beautiful

The color steel plate has clear lines of up to dozens of colors, which can be used to meet the needs of any style of mobile buildings to achieve satisfactory results.

5. composition application

1. The substrate of color steel plate can be divided into cold rolled substrate, hot dip galvanized substrate and electro galvanized substrate.

2. The coating types of color steel plate can be divided into: polyester, silicon modified polyester, vinylidene fluoride, plastisol.

3. The color of the color steel plate can be divided into many types according to the requirements of users, such as orange, milk yellow, deep sky blue, navy, crimson, brick red, ivory, porcelain blue, etc.

4, the surface state of the color steel plate can be divided into coated plate, embossing plate, printing plate.

5. The market use of color coated steel plate is mainly divided into three parts: construction, home appliances and transportation. Among them, the construction field accounts for the largest proportion, followed by the home appliance industry, and the transportation industry only accounts for a small part.

Color steel plates for construction are generally made of hot-dip galvanized steel plates and hot-dip aluminum-zinc steel plates as substrates, which are mainly processed into corrugated plates or composite sandwich panels with polyurethane for the construction of steel structure factories, airports, warehouses, freezers and other industrial and commercial buildings. Roof, wall, door.

Home appliance color plates are generally electrogalvanized and cold plates as substrates for the production of refrigerators and large air conditioning systems, freezers, bread machines, furniture, etc.

In the transportation industry, electro-galvanized and cold plates are generally used as substrates, mainly for oil pans, automotive interior parts, etc.

Get to know Rongda

Application areas

Precision machinery

Petrochemical

Construction field

Construction Machinery

Industrial plant

Automobile Manufacturing

FAQ

If you are interested in this product, please fill in the following information and submit it to us, we will arrange experts to contact us as soon as possible!

Related Products

Related Products