Aluminum zinc plating

Key words:

Aluminum zinc plating

Classification:

Product Description

The hot-dip aluminum-zinc steel plate is a cold-rolled steel plate with various strength and thickness specifications as the base material, and a AL-ZN aluminum-zinc alloy coating is hot-dipped on both sides. The obtained pre-coated steel plate has a mass percentage of about 55% Al aluminum, 43.5 ZN zinc and 1.6 Si silicon in the coating composition. It combines the physical protection and high durability of AL and the electrochemical protection of ZN. In addition, on the surface is a highly decorative bright silver gray and specifications of the fish scale pattern, and has a three-dimensional relief feeling.

The two important elements of the plating plate are zinc, aluminum, aluminum and zinc, three kinds of alloy materials. Zinc is generally represented by Z. Z is the contraction of the English word Zinc. Such as Z80 surface galvanized content of 80 grams per square. Z100 indicates that the galvanizing content is 100 grams per square meter, and so on. The number after Z indicates that the average coating content of galvanized steel coil at three points on both sides is how many grams per square meter. The in stock general materials of hot dip galvanizing on the market are: Z80, Z100, Z120, Z140, Z180, Z275, etc. Aluminum is represented by A. A is an abbreviation of English Aluminum.

The aluminum-zinc compound is added together with Z and A. Such as AZ150. In the aluminized zinc mark, for example, AZ100 indicates that the aluminized zinc is 100 grams per square meter, AZ70 indicates that the aluminized zinc content is 70 grams per square meter, and AZ150 indicates that the aluminized zinc content is 150 grams per square meter. The in stock materials of the aluminum-zinc plate roll on the market are generally: AZ50, AZ70, AZ100, AZ150, AZ180, AZ200.

Hot-dip 55% aluminum-zinc alloy steel plate after 20 years without rust, but the relative galvanized plate about 10 years, 4% aluminum-zinc steel plate about 10 years, 7% aluminum-zinc steel plate about 9 years that corrosion phenomenon. Calculated from the measured value of corrosion weight loss, it can be found that the corrosion resistance of 55% Al-Zn alloy plated steel plate can reach more than 50 years.

Characteristics of 1. hot-dip aluminum-zinc plated steel sheet

1. Good formability (Machinability), to meet the roll stamping forming, bending and other forms of processing requirements.

2. Excellent heat resistance (Thermal resistance), ordinary hot-dip galvanized products usually use temperature does not exceed 230 ℃,250 ℃ will change color, aluminum-zinc plate is different, aluminum-zinc plate can be used for a long time at 315 ℃ environment.

3. Super high reflectivity (High reflectivity), the ability of aluminized zinc to reflect heat and light is 2 times that of hot-dip galvanized steel. The reflectivity is greater than 0.70, which is better than the 0.65 specified by EPA ENERGY STAR. It is an ideal building material for energy saving.

4. Excellent corrosion resistance (Resistance to corrosion), aluminum-zinc plated steel plate has excellent corrosion resistance than the same thickness of hot-dip galvanized steel plate, under the premise of the same thickness and the same zinc layer content, the service life is 2-6 times that of ordinary galvanized steel plate.

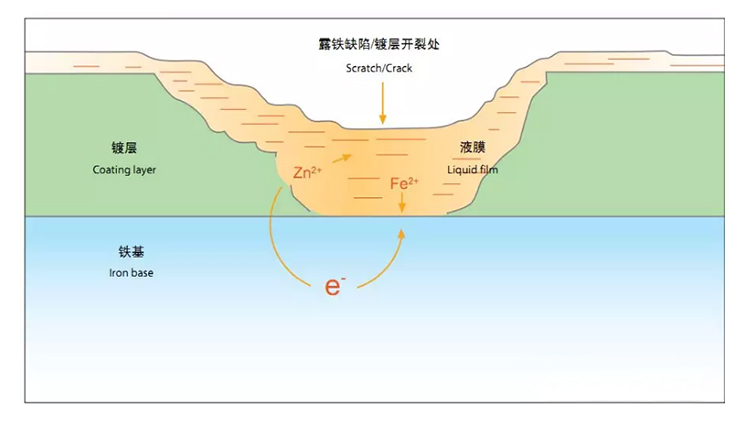

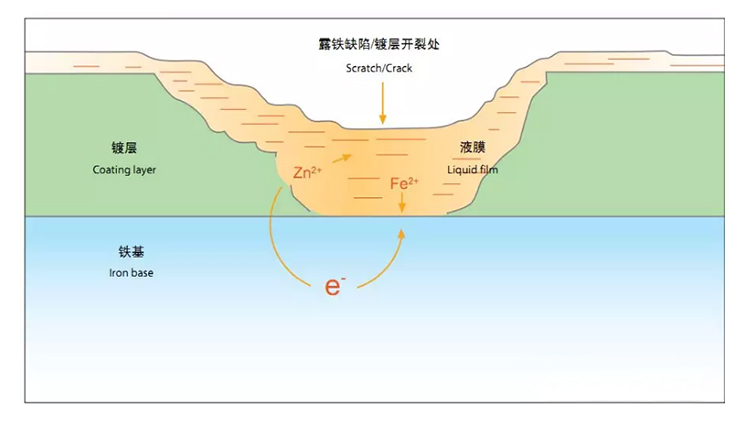

5. The coating of aluminum-zinc steel plate has a good electrochemical protection effect on the steel plate, and the electrochemical effect is analyzed as follows:

An electrochemical protection reaction occurs at the defect:

Anode reaction: ZN-ZE = ZN2 (the coating loses electrons, and the sacrifice dissolves)

Cathode response: FE 2E = FE (iron gets electrons and is protected)

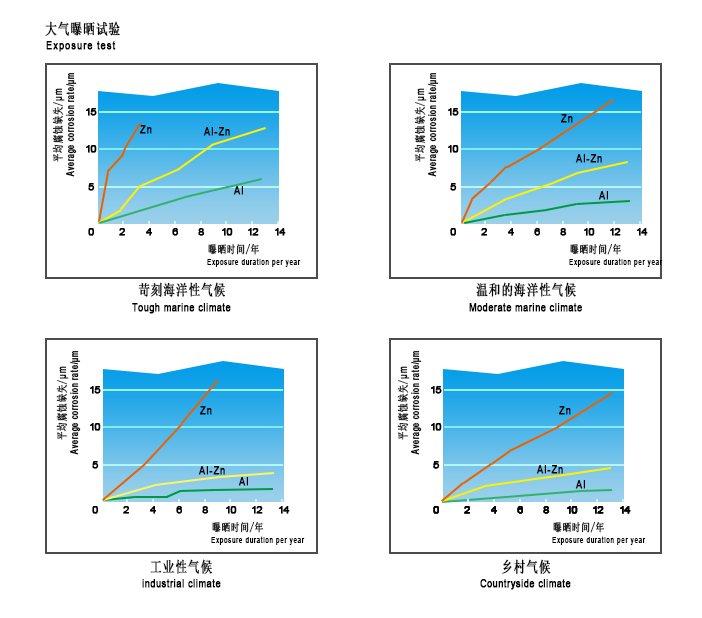

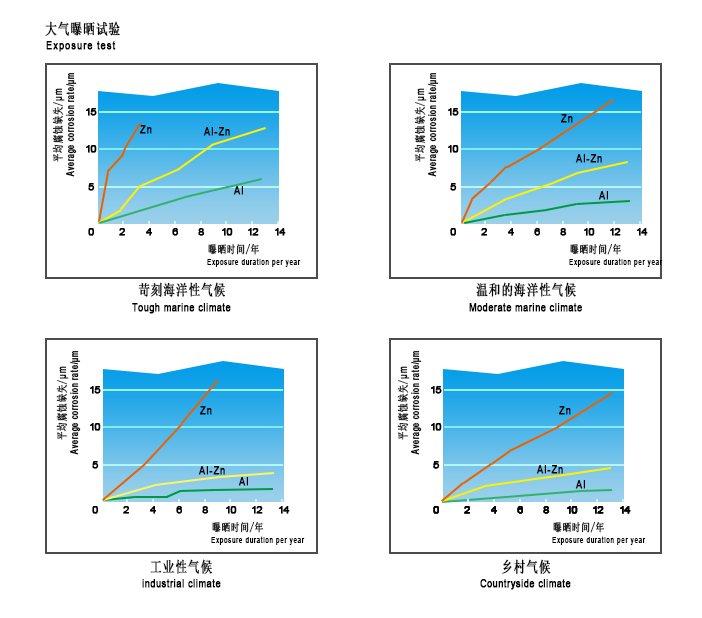

Experiment and test of 3. aluminum-zinc plated steel plate

1. Large steam exposure test of aluminum-zinc plated steel plate

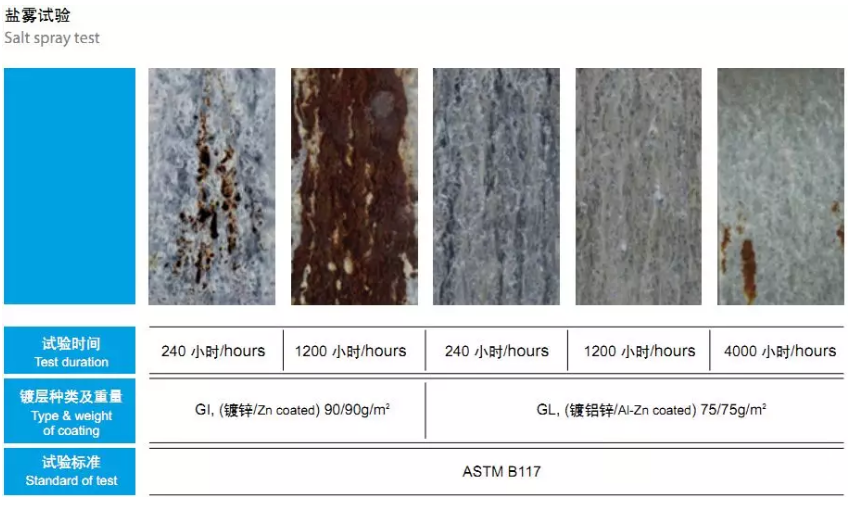

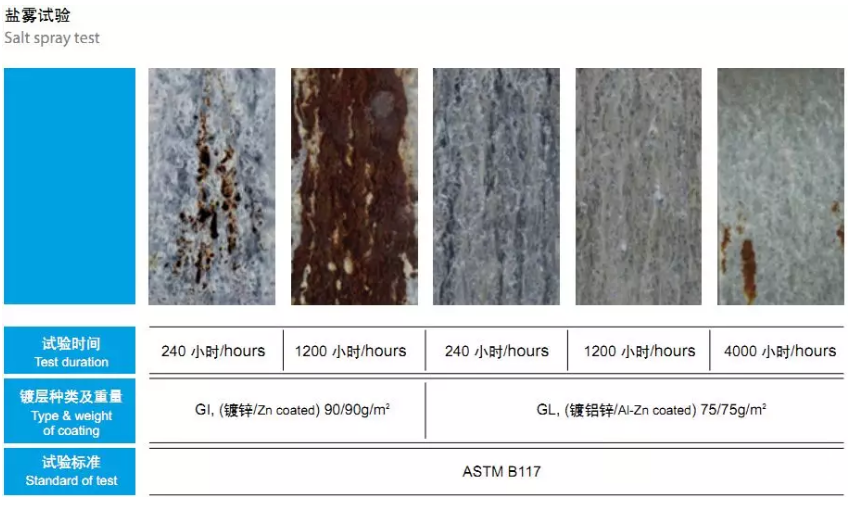

2. The salt spray test of aluminized zinc plate, the salt spray test of aluminized zinc plate is up to 5000 hours/hours, and the test results of aluminized zinc plate under different zinc layer contents are as follows:

Use of 4. aluminum-zinc plated steel sheet

Precautions for use

1. Use aluminum-zinc plated steel plate with caution under the conditions of alkaline medium (strong alkaline introduction is prone to chemical reaction with aluminum medium)

2. The roof of the building with aluminum-zinc steel plate should have a certain slope, which is conducive to drainage and avoid aggravation of corrosion (the minimum slope is not less than 10 degrees)

3. Avoid direct contact with warm cement and wet wood, lead, copper, graphite.

4. Should be used as far as possible to avoid cutting at the site. The incision was exposed to air.

5. Processing, stacking should prevent moisture and high temperature caused by fingerprint-resistant surface film blackening.

6. The aluminum-zinc plated steel plate used for foaming bonding shall be tested in small batch for the first time to prevent poor bonding performance.

7. Surface cleaning does not recommend the use of alcohol-based solvents for wiping and cleaning. If you need to use it, please conduct a small sample test to avoid damage to the surface coating.

Scope of use

Galvanized zinc steel plate is widely used in the construction industry, home appliance industry, industrial installation industry, electrical cabinets, cable tray. Such

Civil and industrial building roofs, exterior walls, painted substrates, garage doors, fences, shutters, ventilation ducts, etc.

Industrial instruments, electrical control cabinets, industrial freezers, automatic vending machines, refrigerators, etc.

- Product Description

-

- Commodity name: Aluminum zinc plating

- Commodity ID: 1268892020319604736

The hot-dip aluminum-zinc steel plate is a cold-rolled steel plate with various strength and thickness specifications as the base material, and a AL-ZN aluminum-zinc alloy coating is hot-dipped on both sides. The obtained pre-coated steel plate has a mass percentage of about 55% Al aluminum, 43.5 ZN zinc and 1.6 Si silicon in the coating composition. It combines the physical protection and high durability of AL and the electrochemical protection of ZN. In addition, on the surface is a highly decorative bright silver gray and specifications of the fish scale pattern, and has a three-dimensional relief feeling. The two important elements of the plating plate are zinc, aluminum, aluminum and zinc, three kinds of alloy materials. Zinc is generally represented by Z. Z is English Zi

The hot-dip aluminum-zinc steel plate is a cold-rolled steel plate with various strength and thickness specifications as the base material, and a AL-ZN aluminum-zinc alloy coating is hot-dipped on both sides. The obtained pre-coated steel plate has a mass percentage of about 55% Al aluminum, 43.5 ZN zinc and 1.6 Si silicon in the coating composition. It combines the physical protection and high durability of AL and the electrochemical protection of ZN. In addition, on the surface is a highly decorative bright silver gray and specifications of the fish scale pattern, and has a three-dimensional relief feeling.

The two important elements of the plating plate are zinc, aluminum, aluminum and zinc, three kinds of alloy materials. Zinc is generally represented by Z. Z is the contraction of the English word Zinc. Such as Z80 surface galvanized content of 80 grams per square. Z100 indicates that the galvanizing content is 100 grams per square meter, and so on. The number after Z indicates that the average coating content of galvanized steel coil at three points on both sides is how many grams per square meter. The in stock general materials of hot dip galvanizing on the market are: Z80, Z100, Z120, Z140, Z180, Z275, etc. Aluminum is represented by A. A is an abbreviation of English Aluminum.

The aluminum-zinc compound is added together with Z and A. Such as AZ150. In the aluminized zinc mark, for example, AZ100 indicates that the aluminized zinc is 100 grams per square meter, AZ70 indicates that the aluminized zinc content is 70 grams per square meter, and AZ150 indicates that the aluminized zinc content is 150 grams per square meter. The in stock materials of the aluminum-zinc plate roll on the market are generally: AZ50, AZ70, AZ100, AZ150, AZ180, AZ200.

Hot-dip 55% aluminum-zinc alloy steel plate after 20 years without rust, but the relative galvanized plate about 10 years, 4% aluminum-zinc steel plate about 10 years, 7% aluminum-zinc steel plate about 9 years that corrosion phenomenon. Calculated from the measured value of corrosion weight loss, it can be found that the corrosion resistance of 55% Al-Zn alloy plated steel plate can reach more than 50 years.

Characteristics of 1. hot-dip aluminum-zinc plated steel sheet

1. Good formability (Machinability), to meet the roll stamping forming, bending and other forms of processing requirements.

2. Excellent heat resistance (Thermal resistance), ordinary hot-dip galvanized products usually use temperature does not exceed 230 ℃,250 ℃ will change color, aluminum-zinc plate is different, aluminum-zinc plate can be used for a long time at 315 ℃ environment.

3. Super high reflectivity (High reflectivity), the ability of aluminized zinc to reflect heat and light is 2 times that of hot-dip galvanized steel. The reflectivity is greater than 0.70, which is better than the 0.65 specified by EPA ENERGY STAR. It is an ideal building material for energy saving.

4. Excellent corrosion resistance (Resistance to corrosion), aluminum-zinc plated steel plate has excellent corrosion resistance than the same thickness of hot-dip galvanized steel plate, under the premise of the same thickness and the same zinc layer content, the service life is 2-6 times that of ordinary galvanized steel plate.

5. The coating of aluminum-zinc steel plate has a good electrochemical protection effect on the steel plate, and the electrochemical effect is analyzed as follows:

An electrochemical protection reaction occurs at the defect:

Anode reaction: ZN-ZE = ZN2 (the coating loses electrons, and the sacrifice dissolves)

Cathode response: FE 2E = FE (iron gets electrons and is protected)

Experiment and test of 3. aluminum-zinc plated steel plate

1. Large steam exposure test of aluminum-zinc plated steel plate

2. The salt spray test of aluminized zinc plate, the salt spray test of aluminized zinc plate is up to 5000 hours/hours, and the test results of aluminized zinc plate under different zinc layer contents are as follows:

Use of 4. aluminum-zinc plated steel sheet

Precautions for use

1. Use aluminum-zinc plated steel plate with caution under the conditions of alkaline medium (strong alkaline introduction is prone to chemical reaction with aluminum medium)

2. The roof of the building with aluminum-zinc steel plate should have a certain slope, which is conducive to drainage and avoid aggravation of corrosion (the minimum slope is not less than 10 degrees)

3. Avoid direct contact with warm cement and wet wood, lead, copper, graphite.

4. Should be used as far as possible to avoid cutting at the site. The incision was exposed to air.

5. Processing, stacking should prevent moisture and high temperature caused by fingerprint-resistant surface film blackening.

6. The aluminum-zinc plated steel plate used for foaming bonding shall be tested in small batch for the first time to prevent poor bonding performance.

7. Surface cleaning does not recommend the use of alcohol-based solvents for wiping and cleaning. If you need to use it, please conduct a small sample test to avoid damage to the surface coating.

Scope of use

Galvanized zinc steel plate is widely used in the construction industry, home appliance industry, industrial installation industry, electrical cabinets, cable tray. Such

Civil and industrial building roofs, exterior walls, painted substrates, garage doors, fences, shutters, ventilation ducts, etc.

Industrial instruments, electrical control cabinets, industrial freezers, automatic vending machines, refrigerators, etc.

Get to know Rongda

Application areas

Precision machinery

Petrochemical

Construction field

Construction Machinery

Industrial plant

Automobile Manufacturing

FAQ

If you are interested in this product, please fill in the following information and submit it to us, we will arrange experts to contact us as soon as possible!

Related Products

Related Products