Opening plate

Key words:

Opening plate

Classification:

Product Description

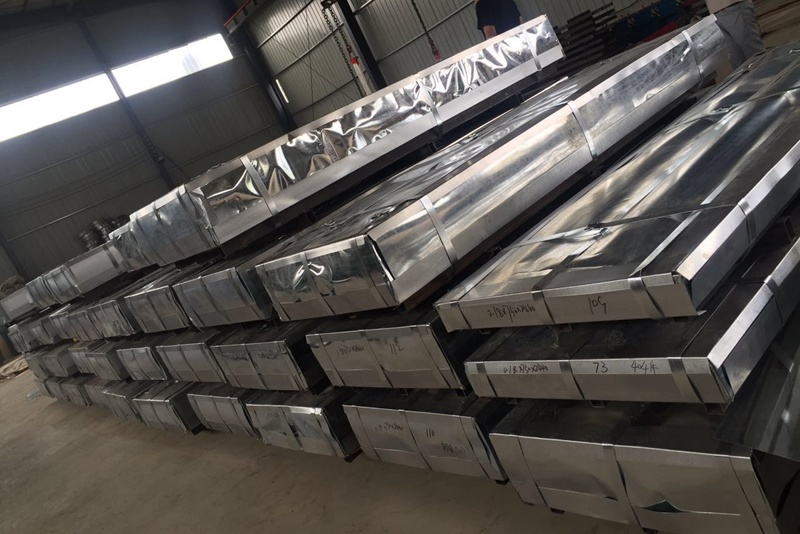

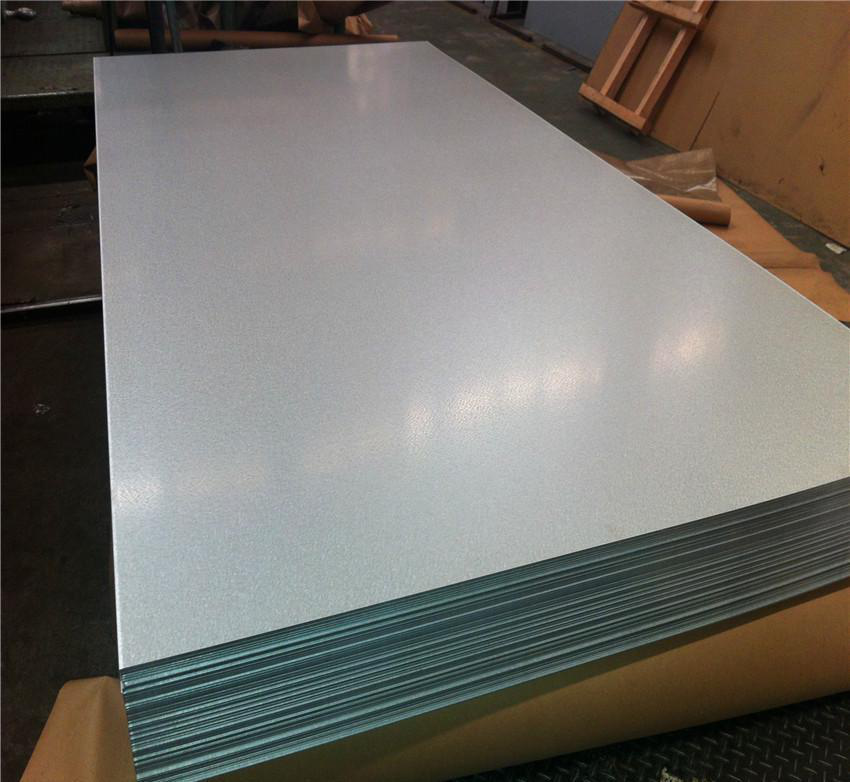

In recent years, in order to meet the needs of more and more customers, we have extended the Kaiping service vertically. On the basis of using our own galvanized, aluminized zinc and color coated substrates, we can provide our customers with excellent quality open plates. Open plate is commonly known as shear steel plate, shear steel plate belongs to the metallurgical mineral industry, subdivided into a category of coating products, has been recognized by the majority of customers. In the revised GB709, the open plate and the original plate should be called: single rolled steel plate and shear steel plate.

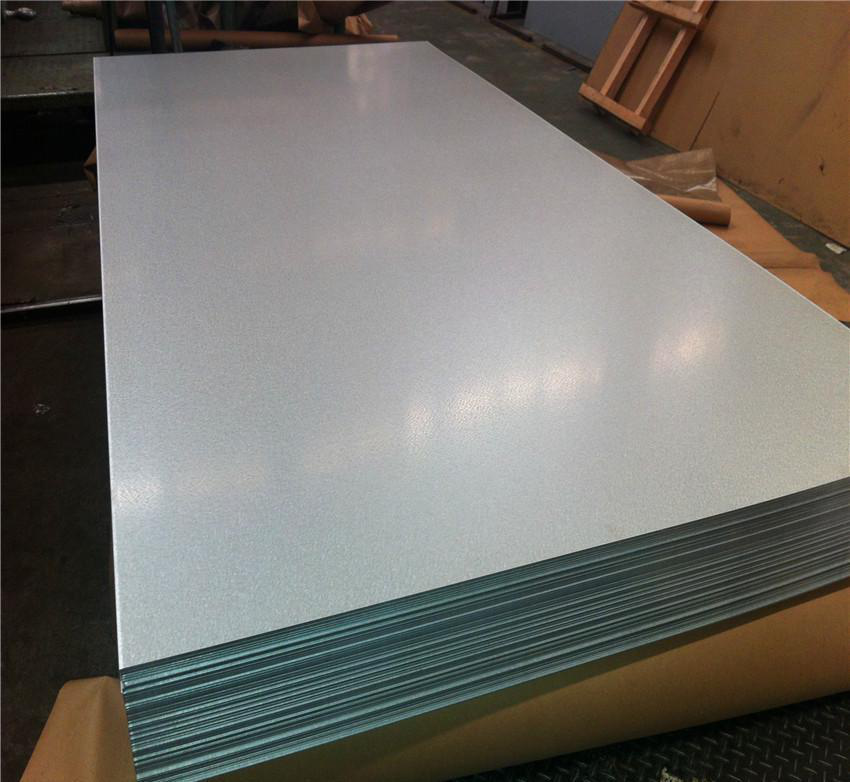

When the steel plate comes out of the steel mill, it is rolled. The flat plate after these steel plates are leveled by the Kaiping machine is called "open plate", just like the whole roll of toilet paper. The internal stress level of the open plate is higher, so the dimensional stability is poor. With the different process parameters of Kaiping operation, the internal stress distribution is also different, and the bearing capacity will be different in different directions of vertical length. And this carrying capacity is difficult to measure with general strength indicators. Therefore, the open plate will have great welding deformation during welding, which is difficult to adjust. Therefore, the appearance of high quality components can not use the open plate.

Open plate is cheaper than ordinary steel plate. The thickness is 1.5-20mm, the material is Q235 and Q345, and the main use is on non-pressurized containers and storage tanks.

The open plate was originally a steel strip with a certain thickness when leaving the factory. It is a steel plate with a certain thickness and width rolled according to user requirements.

The advantages of open plate:

1. The price is cheap and the length can be freely decided;

2. Convenient transportation, regardless of the size of the steel plate;

3. The material is convenient, and the material can be cut according to the actual needs of the steel plate size;

4. Can effectively save materials.

Disadvantages of open plate:

The disadvantage is that there will be great welding deformation during welding, which is difficult to adjust. Therefore, the appearance of high quality components can not use the open plate.

open plate with the original plate of distinction:

There is no difference between the mechanical properties of the open plate and the original plate. The main difference is in the board of the product. The factory original flat plate is smoother than the open flat plate. The open flat plate is cut after the original roll is leveled by the leveler. After a break, sickle bending of the original roll may occur.

The original flat plate is generally four-cut edge, open flat plate unless special requirements, are generally two-cut edge.

The tolerance of the open plate in thickness can be larger than that of the original plate.

If the flatness of the board is not very high, you can use the open plate.

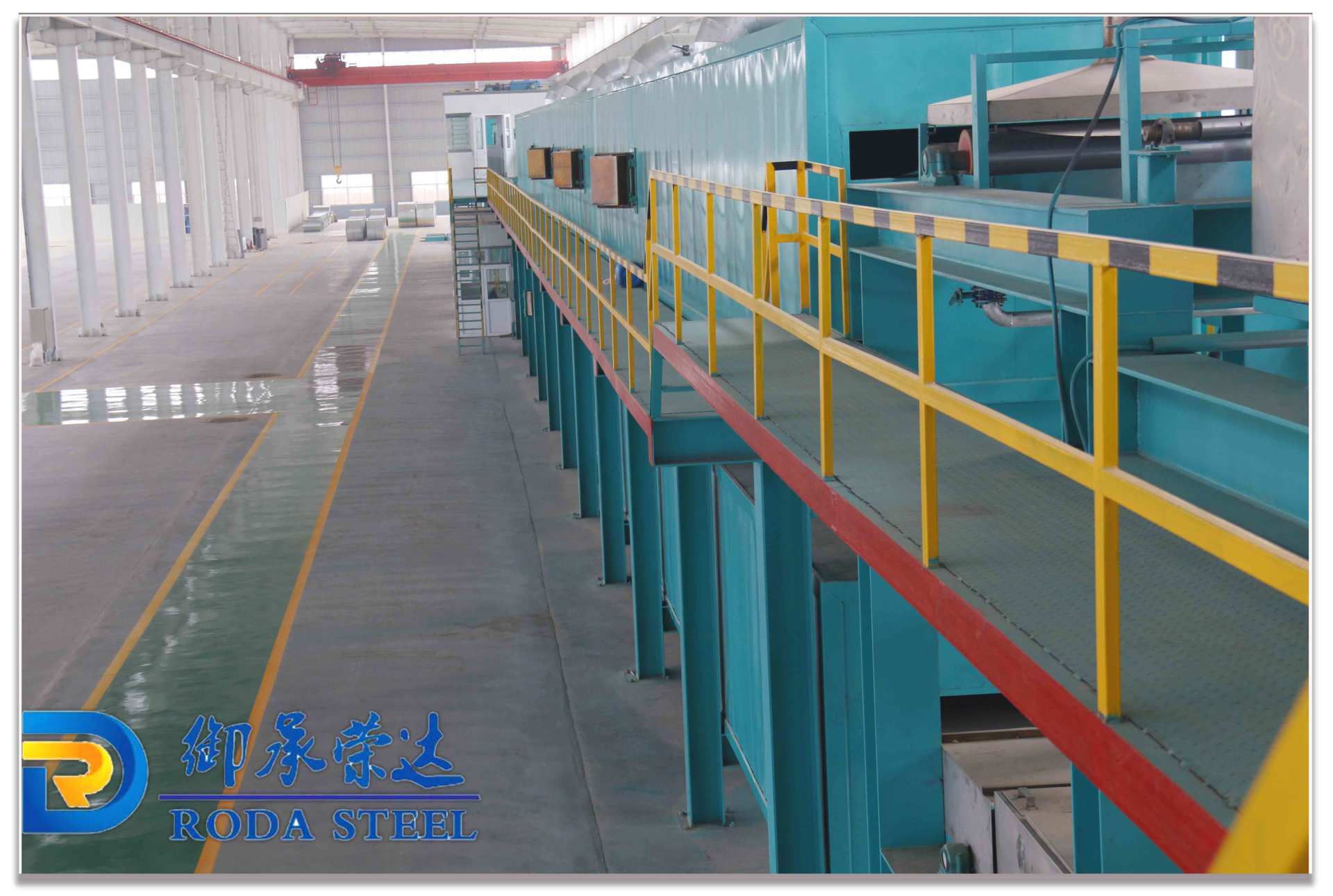

Our company's production of open plate must go through strict quality inspection procedures to ensure that each process is better. In particular, the number of meters and pieces that customers are most concerned about, we have to go through strict inspection before the products leave the factory to ensure the accuracy of the quantity. In addition, in order to make the product surface smooth and beautiful, we have been adjusting the process improvement technology, and strive to bring customers the best quality experience.

- Product Description

-

- Commodity name: Opening plate

- Commodity ID: 1268891996055556096

In recent years, in order to meet the needs of more and more customers, we have extended the Kaiping service vertically. On the basis of using our own galvanized, aluminized zinc and color coated substrates, we can provide our customers with excellent quality open plates. Open plate is commonly known as shear steel plate, shear steel plate belongs to the metallurgical mineral industry, subdivided into a category of coating products, has been recognized by the majority of customers. In the revised GB709, the open plate and the original plate should be called: single rolled steel plate and shear steel plate. When the steel plate comes out of the steel mill, it is rolled. The flat plate after these steel plates are leveled by the leveler is called "open plate", which is good.

In recent years, in order to meet the needs of more and more customers, we have extended the Kaiping service vertically. On the basis of using our own galvanized, aluminized zinc and color coated substrates, we can provide our customers with excellent quality open plates. Open plate is commonly known as shear steel plate, shear steel plate belongs to the metallurgical mineral industry, subdivided into a category of coating products, has been recognized by the majority of customers. In the revised GB709, the open plate and the original plate should be called: single rolled steel plate and shear steel plate.

When the steel plate comes out of the steel mill, it is rolled. The flat plate after these steel plates are leveled by the Kaiping machine is called "open plate", just like the whole roll of toilet paper. The internal stress level of the open plate is higher, so the dimensional stability is poor. With the different process parameters of Kaiping operation, the internal stress distribution is also different, and the bearing capacity will be different in different directions of vertical length. And this carrying capacity is difficult to measure with general strength indicators. Therefore, the open plate will have great welding deformation during welding, which is difficult to adjust. Therefore, the appearance of high quality components can not use the open plate.

Open plate is cheaper than ordinary steel plate. The thickness is 1.5-20mm, the material is Q235 and Q345, and the main use is on non-pressurized containers and storage tanks.

The open plate was originally a steel strip with a certain thickness when leaving the factory. It is a steel plate with a certain thickness and width rolled according to user requirements.

The advantages of open plate:

1. The price is cheap and the length can be freely decided;

2. Convenient transportation, regardless of the size of the steel plate;

3. The material is convenient, and the material can be cut according to the actual needs of the steel plate size;

4. Can effectively save materials.

Disadvantages of open plate:

The disadvantage is that there will be great welding deformation during welding, which is difficult to adjust. Therefore, the appearance of high quality components can not use the open plate.

open plate with the original plate of distinction:

There is no difference between the mechanical properties of the open plate and the original plate. The main difference is in the board of the product. The factory original flat plate is smoother than the open flat plate. The open flat plate is cut after the original roll is leveled by the leveler. After a break, sickle bending of the original roll may occur.

The original flat plate is generally four-cut edge, open flat plate unless special requirements, are generally two-cut edge.

The tolerance of the open plate in thickness can be larger than that of the original plate.

If the flatness of the board is not very high, you can use the open plate.

Our company's production of open plate must go through strict quality inspection procedures to ensure that each process is better. In particular, the number of meters and pieces that customers are most concerned about, we have to go through strict inspection before the products leave the factory to ensure the accuracy of the quantity. In addition, in order to make the product surface smooth and beautiful, we have been adjusting the process improvement technology, and strive to bring customers the best quality experience.

Get to know Rongda

Application areas

Precision machinery

Petrochemical

Construction field

Construction Machinery

Industrial plant

Automobile Manufacturing

FAQ

If you are interested in this product, please fill in the following information and submit it to us, we will arrange experts to contact us as soon as possible!

Related Products

Related Products