Galvanized-no zinc flower

Key words:

Galvanized-no zinc flower

Classification:

Product Description

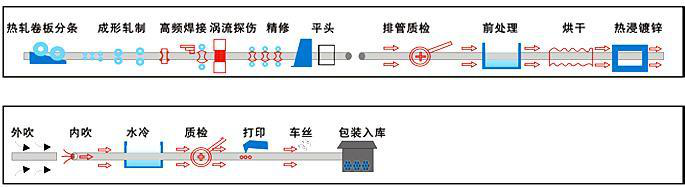

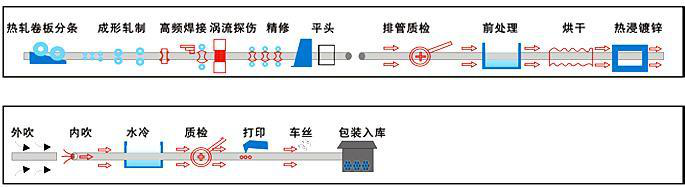

Galvanized Sheet-Process Flow

Production process

A, cold and hot rolled steel plate by alkaline degreasing, and water washing, drying and then into the radiation tube heating horizontal (vertical) furnace for annealing, furnace into a certain amount of hydrogen to create a reducing atmosphere;

B, heated to a certain temperature of the steel strip under certain conditions immersed in zinc hot dip galvanizing. After the strip steel immersed in the zinc liquid comes out of the zinc pot, the amount of galvanizing is controlled by an air knife;

C, zinc flower size by the composition of liquid zinc to control at the same time, the use of forced cooling method to control, small zinc flower products in the zinc flower began to spread before, with small zinc flower equipment for quenching to prevent zinc liquid to continue to spread, the formation of small zinc flower;

D, after hot galvanizing strip steel cooling through the surface finishing, and finally according to the use, respectively, the surface passivation treatment or direct production into color coated coil.

According to the classification of coating methods:

a. Hot-dip galvanized steel sheet

B. Electro-galvanized steel sheet

Types and Uses of Galvanized Sheet

|

Non-alloying (Galvanized) |

alloying |

||

|

general zinc flower |

Fine (no) zinc flower |

Ultra-smooth Surface Extra-smooth |

|

|

The zinc coating cures in the normal way to produce zinc flowers. |

Before the galvanized layer is cured, the zinc powder or steam is blown to control the crystallization of zinc flowers or the composition of the plating bath.fine zinc floweror calledzinc-free flowers |

After galvanizing, it is quenched and tempered, resulting in a smooth surface. |

After the steel strip is out of the zinc bath, it is treated in an alloying furnace to form a zinc-iron alloy layer. |

|

general zinc flower |

Fine (no) zinc flower |

Ultra-smooth Surface Extra-smooth |

alloying |

|

Good adhesion |

The surface is slightly smooth, and the surface is even after painting. |

The surface is relatively smooth, and the surface is uniform and beautiful after painting |

Rough surface without zinc flower, good coating and good weldability |

|

general zinc flower |

Fine (no) zinc flower |

Ultra-smooth surface |

alloying |

|

Most applicable: anti-shaped guardrail, blower, air duct, duct |

Most applicable: drainage pipe, ceiling bracket, wire conduit, rolling door edge center column, color coated substrate |

Most applicable: drainage pipe, automobile components, electrical equipment, freezer, color coated substrate |

Most applicable: iron rolling door, sign, car body, vending machine, refrigerator, washing machine, display cabinet |

Product indicators and representation

A, zinc layer adhesion: under normal circumstances Z10, Z12, Z18 said the amount of zinc per square meter is 100 grams, 120 grams, 180 grams;

Application of Galvanized Sheet for Building

A, housing construction roof or processing color coated board

B. Construction site fence

C, thermal pipeline insulation skin

d. Formwork support for buildings and bridges

e. Air-conditioning duct

f. Steel plate warehouse

g. Chimneys of rural houses

h. Fume hood

I. advertising board

Wait...

Quality Defects and Precautions of Galvanized Sheet

A, galvanized sheet common quality defects

1. Defect name: galvanized stripping

Defect performance: dezincification

Causes: poor furnace temperature, improper substrate handling, etc.

2. Name of defect: ungalvanized

Defect performance: the surface part of the steel plate is not galvanized

Causes: poor raw materials, poor pretreatment degreasing, poor furnace temperature

3. Defect name: zinc flower bad

Defect performance: zinc flower size is not uniform, no zinc flower

Cause: poor heating of furnace area and poor cooling control

4. Defect name: zinc scar

Defect performance: steel plate surface point, granular zinc slag adhesion

Cause: scum or bottom slag in zinc pot adheres to steel strip

5. Defect name: oxidation

Defect performance: produce white rust

Cause: in the process of storage, absorption of moisture in the air, oxidation

2Zn O2 → 2ZnO

5ZnO 2CO2 3H2O →2ZnCO3·3Zn(OH)2

6. Defect Name: Black Spot

Defect performance: black dot, block spots

Cause: impure precipitation reacts with moisture and carbon dioxide in the atmosphere, or friction during transportation.

7. Name of defect: side wave and medium wave

Defect performance: the edge or middle is wavy

Cause: poor raw materials or poor working condition of straightening roller

8. Defect name: jagged edge

Defect performance: the edge is sawtooth shape

Cause of occurrence: the edges are uneven and serrated when the raw materials are cold-bound.

9. Defect name: uneven board surface

Defect Manifestations: Dents

Cause: raw material pits or roller surface foreign matter adhesion

B, galvanized coil transportation and storage should pay attention to matters

1. Choose a ventilated place to store in the house to avoid dew erosion or moisture penetration

2. Confirm that the wrapping paper is not damaged during storage.

Shorten the storage time as much as possible and protect its surface before corrosion.

4. If the plate is subjected to abnormal external pressure, the zinc layer will partially fall off.

5. It is necessary to prevent dirt and oil powder from sticking to the surface, which will affect the galvanizing effect.

6, steel coil below should be added with wood or support frame, stacking layer should not exceed two layers

7, transportation should be covered with rain cloth, and must be used with wood pads and rubber pads, fixed with ropes

- Product Description

-

- Commodity name: Galvanized-no zinc flower

- Commodity ID: 1268892006709088256

Galvanized plate-process flow production process a, cold and hot rolled steel plate is degreased by alkali washing, washed with water, dried and then annealed in a horizontal (vertical) heating furnace heated by radiant tubes, and a certain amount of hydrogen is introduced into the furnace to create a reducing atmosphere in the furnace; B, steel strip heated to a certain temperature is immersed in zinc solution for hot dip galvanizing under certain conditions. After the strip steel immersed in zinc liquid comes out of the zinc pot, the amount of zinc plating is controlled by an air knife. C, the size of zinc flower is controlled by the composition of liquid zinc, and at the same time, the forced cooling method is adopted. Before the zinc flower starts to diffuse, the small zinc flower product is quenched with the small zinc flower equipment to prevent the zinc liquid from continuing to diffuse and form small zinc flower.

Galvanized Sheet-Process Flow

Production process

A, cold and hot rolled steel plate by alkaline degreasing, and water washing, drying and then into the radiation tube heating horizontal (vertical) furnace for annealing, furnace into a certain amount of hydrogen to create a reducing atmosphere;

B, heated to a certain temperature of the steel strip under certain conditions immersed in zinc hot dip galvanizing. After the strip steel immersed in the zinc liquid comes out of the zinc pot, the amount of galvanizing is controlled by an air knife;

C, zinc flower size by the composition of liquid zinc to control at the same time, the use of forced cooling method to control, small zinc flower products in the zinc flower began to spread before, with small zinc flower equipment for quenching to prevent zinc liquid to continue to spread, the formation of small zinc flower;

D, after hot galvanizing strip steel cooling through the surface finishing, and finally according to the use, respectively, the surface passivation treatment or direct production into color coated coil.

According to the classification of coating methods:

a. Hot-dip galvanized steel sheet

B. Electro-galvanized steel sheet

Types and Uses of Galvanized Sheet

Non-alloying (Galvanized)alloying

Galvannealedgeneral zinc flower

Regular SpangleFine (no) zinc flower

Minimized (zero) SpangleUltra-smooth Surface Extra-smooth

The zinc coating cures in the normal way to produce zinc flowers.

Before the galvanized layer is cured, the zinc powder or steam is blown to control the crystallization of zinc flowers or the composition of the plating bath.fine zinc floweror calledzinc-free flowers

After galvanizing, it is quenched and tempered, resulting in a smooth surface.

After the steel strip is out of the zinc bath, it is treated in an alloying furnace to form a zinc-iron alloy layer.

general zinc flower

Regular SpangleFine (no) zinc flower

Minimized (zero) SpangleUltra-smooth Surface Extra-smooth

alloying

GalvannealedGood adhesion

Good weather resistanceThe surface is slightly smooth, and the surface is even after painting.

The surface is relatively smooth, and the surface is uniform and beautiful after painting

Rough surface without zinc flower, good coating and good weldability

general zinc flower

Fine (no) zinc flower

Ultra-smooth surface

alloying

Most applicable: anti-shaped guardrail, blower, air duct, duct

Application: iron rolling door, drain pipe, ceiling bracketMost applicable: drainage pipe, ceiling bracket, wire conduit, rolling door edge center column, color coated substrate

Applicable: car body, anti-shaped guardrail, blowerMost applicable: drainage pipe, automobile components, electrical equipment, freezer, color coated substrate

Applicable: car body, anti-shaped guardrail, blowerMost applicable: iron rolling door, sign, car body, vending machine, refrigerator, washing machine, display cabinet

Application: electrical equipment shell, office desk cabinetProduct indicators and representation

A, zinc layer adhesion: under normal circumstances Z10, Z12, Z18 said the amount of zinc per square meter is 100 grams, 120 grams, 180 grams;

Application of Galvanized Sheet for Building

A, housing construction roof or processing color coated board

B. Construction site fence

C, thermal pipeline insulation skin

d. Formwork support for buildings and bridges

e. Air-conditioning duct

f. Steel plate warehouse

g. Chimneys of rural houses

h. Fume hood

I. advertising board

Wait...

Quality Defects and Precautions of Galvanized Sheet

A, galvanized sheet common quality defects

1. Defect name: galvanized stripping

Defect performance: dezincification

Causes: poor furnace temperature, improper substrate handling, etc.

2. Name of defect: ungalvanized

Defect performance: the surface part of the steel plate is not galvanized

Causes: poor raw materials, poor pretreatment degreasing, poor furnace temperature

3. Defect name: zinc flower bad

Defect performance: zinc flower size is not uniform, no zinc flower

Cause: poor heating of furnace area and poor cooling control

4. Defect name: zinc scar

Defect performance: steel plate surface point, granular zinc slag adhesion

Cause: scum or bottom slag in zinc pot adheres to steel strip

5. Defect name: oxidation

Defect performance: produce white rust

Cause: in the process of storage, absorption of moisture in the air, oxidation

2Zn O2 → 2ZnO

5ZnO 2CO2 3H2O →2ZnCO3·3Zn(OH)2

6. Defect Name: Black Spot

Defect performance: black dot, block spots

Cause: impure precipitation reacts with moisture and carbon dioxide in the atmosphere, or friction during transportation.

7. Name of defect: side wave and medium wave

Defect performance: the edge or middle is wavy

Cause: poor raw materials or poor working condition of straightening roller

8. Defect name: jagged edge

Defect performance: the edge is sawtooth shape

Cause of occurrence: the edges are uneven and serrated when the raw materials are cold-bound.

9. Defect name: uneven board surface

Defect Manifestations: Dents

Cause: raw material pits or roller surface foreign matter adhesion

B, galvanized coil transportation and storage should pay attention to matters

1. Choose a ventilated place to store in the house to avoid dew erosion or moisture penetration

2. Confirm that the wrapping paper is not damaged during storage.

Shorten the storage time as much as possible and protect its surface before corrosion.

4. If the plate is subjected to abnormal external pressure, the zinc layer will partially fall off.

5. It is necessary to prevent dirt and oil powder from sticking to the surface, which will affect the galvanizing effect.

6, steel coil below should be added with wood or support frame, stacking layer should not exceed two layers

7, transportation should be covered with rain cloth, and must be used with wood pads and rubber pads, fixed with ropes

Get to know Rongda

Application areas

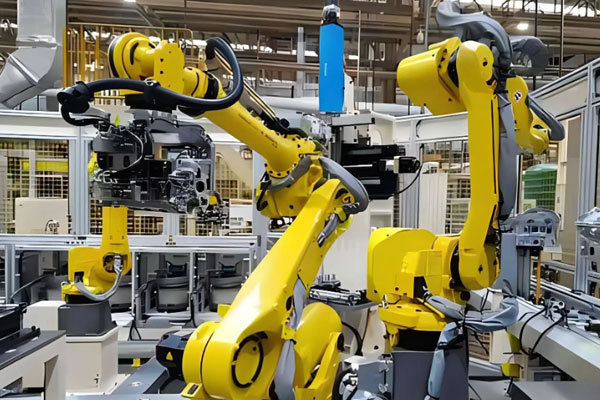

Precision machinery

Petrochemical

Construction field

Construction Machinery

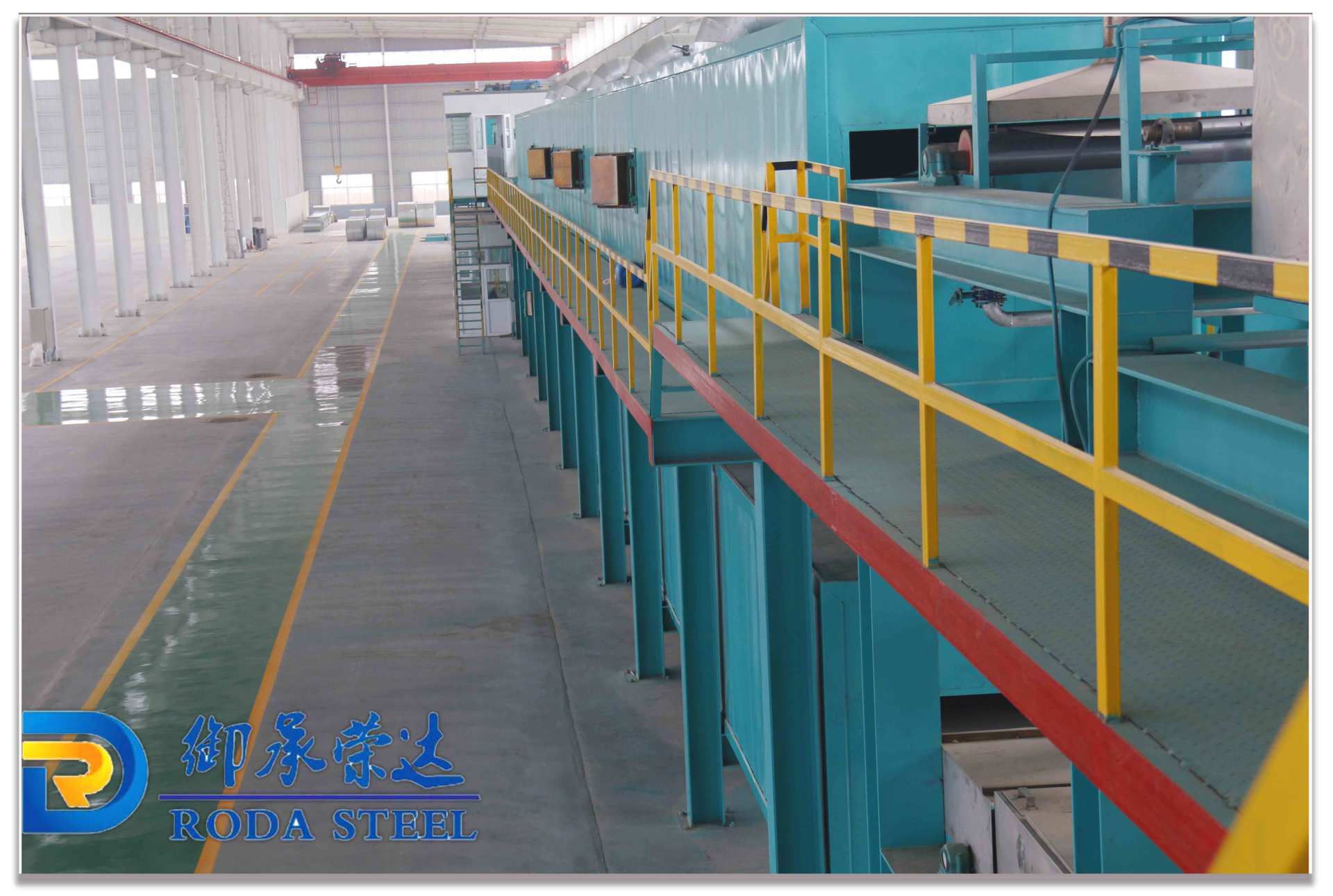

Industrial plant

Automobile Manufacturing

FAQ

If you are interested in this product, please fill in the following information and submit it to us, we will arrange experts to contact us as soon as possible!

Related Products

Related Products